The Precision Craft of Diecasting: Revolutionizing Manufacturing

The Precision Craft of Diecasting: Revolutionizing Manufacturing

Blog Article

Diecasting is a diverse and popular manufacturing technique that involves injecting molten metal into mold cavities under intense pressure. It's a highly effective method for producing large volumes of intricate metal components that have excellent accuracy in dimensional measurement and a smooth surface finish. The method, material, and the applications of diecasting can be utilized in a wide range of industries, making it an essential component of modern manufacturing. This article outlines the basics of diecasting as well as its strengths as well as its numerous applications within the manufacturing industry.

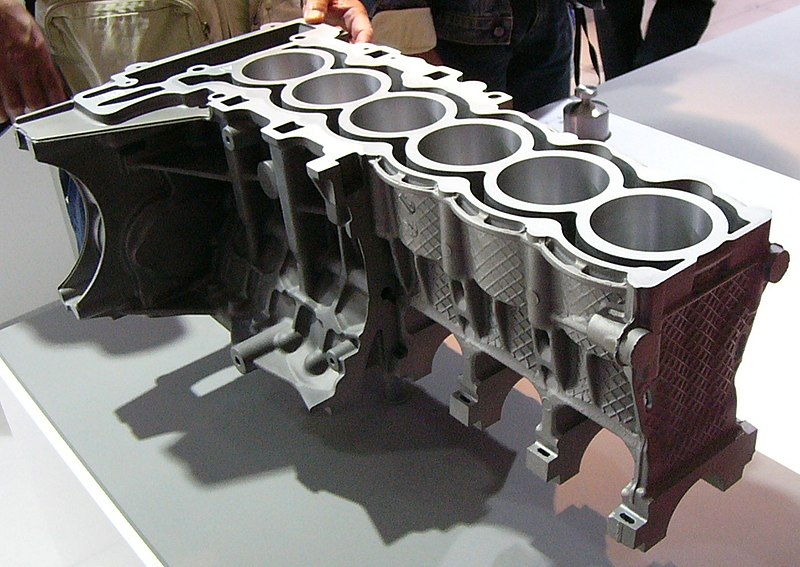

Diecasting is the utilization of molds, also referred to as dies. They are made with high-quality steel in order to stand up to the tough conditions encountered in diecasting. Dies are created using precision and often incorporate elaborate details and precise tolerances that ensure that the finished product is accurate. In the process of diecasting, melting metal - commonly aluminum, zinc or magnesium is being injected into the dies using very high pressure. Rapid injection and rapid the process of solidification results in parts with exceptional dimensional stability, as well as a polished surface, which reduces the requirement for additional processing or finishing. The high precision of dies allows the fabrication of complex geometries that are difficult or impossible to attain using conventional manufacturing techniques.

One of the major advantages of diecasting is the capacity to make parts with exceptional dimensional accuracy and smooth surfaces. This is because high-pressure injection makes sure that every part of the mold has been replicated, resulting in parts with tight tolerances, and need minimal or any post-production effort. This accuracy is particularly useful to create complex geometries and fine details that might be challenging or impossible to accomplish by other techniques of manufacture. Also, the repeatability of diecasting makes it a great choice for large-scale production, ensuring uniformity across a large number of parts. Diecasting's efficiency is also a major source of reductions in costs, since it helps reduce waste materials as well as labor expenses.

Diecasting is extensively used in diverse industries due to its versatility as well as the variety of different materials used. In the automotive industry, diecast parts are essential for producing components such as engines, transmission cases, and structural parts. Aerospace relies on diecasting for lightweight and strong parts that are able to endure the harsh conditions of flight. In electronics for consumers, diecasting components are employed for housings and frames, providing the durability and accuracy required in electronic devices. The versatility of diecasting also can be applied to communications, medical, and power tool industries, demonstrating its broad use and significance. To find more information please look at Senadiecasting

The selection of the materials used in diecasting is a major factor in the quality and performance of the final product. Aluminium is an extremely popular material due to its outstanding strength-to-weight ratio, resistance to corrosion, along with its excellent electrical and thermal conductivity. This makes aluminum the ideal material for aerospace and automotive uses where weight reduction is crucial. Zinc alloys provide high strength as well as ductility. These make them suitable for parts requiring fine details and durability. Magnesium alloys are among the lightest metallic structural elements, offering benefits in situations where weight reduction is crucial. Copper alloys, though used less frequently they are highly valued due to their high electrical conductivity and durability to corrosion. Each material offers unique benefits, allowing manufacturers to select the best option for their particular application requirements.

Diecasting is an advanced manufacturing method that is able to combine accuracy, precision as well as versatility. The capability to make sophisticated, high-end components that have exceptional mechanical properties makes it indispensable in many sectors. Diecasting's effectiveness as a mass-production process, coupled with its cost and material advantages, demonstrates its significance for modern manufacturing. While industries are continuing to require robust and high-performance components, diecasting will remain the foundational technology for advancement and the creation of high-quality products that can meet the ever-evolving needs of the market. By its continual evolution and application, diecasting exemplifies the intersection of engineering excellence and manufacturing proficiency.